Additional equipment: self-made capacitors

If you've got a low-current hv dc source, but want to make

high-current sparks, you need a capacitor. Basically, it's not

difficult to make your own cap. You only need aluminium foil and a

piece of (rather thick) plastic of suitable shape, such as foil, tube,

disc etc.

very simple cap

One of the simplest possibilities is a 50 cm long, 10cm diameter PVC

tube (2-3mm

thick walls) with aluminium foil on both surfaces. Leave about 10cm

plastic uncovered at each end. This type has a quite high capacity and

is usable with up to 30kV. The tube would withstand even more,

but the edges of the alu foil would begin to spray then. Use this cap

to get bright, high-current discharges from a TV-cascade (especially

when it's driven by a simple mains transformer).

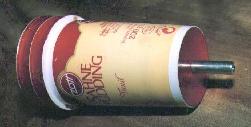

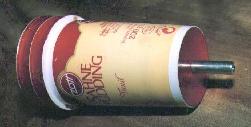

30kV yoghurt container cap

A more elaborate version (sealed airtight, no spraying, no arcing)

is the following:

Get three same plastic

yoghurt containers (PE or PP and rather thick; "Zott Sahnepudding"

serves well and tastes o.k.:-). Also get self-adhesive

aluminium tape (7cm wide). You may find this in DIY markets, it's

original purpose is to seal heat-isolations on hot-water pipe. Put it

on the inside and outside of one container. Fix some kind of terminal

on each of the two others. Connect the terminals to the inside

resp. outside alu layer with a narrow band of alu foil. The three

containers must still fit into one another! Fill some polyester resin

(with hardener of course) into the "outer" and "inner" container and

press all three into one another. Expect the polyester resin to splash

out :-) When the resin has hardened (some hours), the cap is ready and

can be tested. With a not too thin container, it should easily

withstand 30kV. However, the capacity is low due to the small

conducting surface (maybe some 100pF).

A more elaborate version (sealed airtight, no spraying, no arcing)

is the following:

Get three same plastic

yoghurt containers (PE or PP and rather thick; "Zott Sahnepudding"

serves well and tastes o.k.:-). Also get self-adhesive

aluminium tape (7cm wide). You may find this in DIY markets, it's

original purpose is to seal heat-isolations on hot-water pipe. Put it

on the inside and outside of one container. Fix some kind of terminal

on each of the two others. Connect the terminals to the inside

resp. outside alu layer with a narrow band of alu foil. The three

containers must still fit into one another! Fill some polyester resin

(with hardener of course) into the "outer" and "inner" container and

press all three into one another. Expect the polyester resin to splash

out :-) When the resin has hardened (some hours), the cap is ready and

can be tested. With a not too thin container, it should easily

withstand 30kV. However, the capacity is low due to the small

conducting surface (maybe some 100pF).

Hint: When polyester resin reacts with the hardener (forming a

polymer), it produces heat. If you use more hardener, the resin will

harden faster (sounds logical, doesn't it?). However, it will also

develop the same heat in shorter time, and this means higher

temperature! Actually, the thing can get so hot it melts the plastic

containers. So better be patient.

2nF/30kV plate stack capacitor

The capacity of the above "yoghurt container" cap is by far too low for many purposes. This plate stack cap is intended to be used in a tesla coil circuit and a marx generator. It is designed to withstand at least 30kV DC or 20kV AC with a big safety margin. The dielectric is polyethylen (PE), therefore losses should be low even at higher frequencies. The condcting plates (aluminium foil) are al in parallel, making low internal resistance and inductance. Both low losses and low resistance are important for tesla coil and pulse discharge use.

The capacity of the above "yoghurt container" cap is by far too low for many purposes. This plate stack cap is intended to be used in a tesla coil circuit and a marx generator. It is designed to withstand at least 30kV DC or 20kV AC with a big safety margin. The dielectric is polyethylen (PE), therefore losses should be low even at higher frequencies. The condcting plates (aluminium foil) are al in parallel, making low internal resistance and inductance. Both low losses and low resistance are important for tesla coil and pulse discharge use.

The stack consists of 20 insulating layers (each one having 10 sheets of 100microns PE foil) between 21 sheets of aluminium. I usesd the standard PE foil available in DIY markets (watch out for the thickness!), which is rather bad quality. Therefore you should have a close look at every sheet cut, and reject those with visible flaws (grains, small holes). I rejected nearly every fourth sheet. The dimensions should be taylored to your needs (e.g. the container you plan to use). It is important to have the PE sheets somewhat larger than than the aluminium ones - about 1cm at each edge, 2cm at the connection strips. When you cut the shhets, you will probably have most of them a mm or two shorter than planned. You can even out this by stacking every other PE sheet shifted a little. See the figures for dimensions I used.

The complete stack must be tightly compressed to keep it in place and to remove air and increase capacitance. I achieved this by putting te stack between two slightly larger PVC plates, which where then tightened together with four screws in the corners.

To suppress corona and arcing over the foil edges, the stack is immersed in mineral oil (kerosene for its low viscosity). The biggest difficulty is to find a suitable tight container for this. I found PE sandwich container useful. Unfortunately, they are very difficult to glue, so I "welded" the lid tight using a soldering iron. You have to be quite careful doing this, as you have to melt both lid and container for a good connection, but don't want to burn a hole. After sealing, make small hole and fill with oil - leave as less air as possible. The small hole is easily welded tight afterwards (some extra PE to fill the hole). The PE sheets will soak with kerosene and expand somewhat, becoming a little uneven. This does not seem to have any undesirable effects.

A capacitor with the dimensions as above will have about 2nF capacitance. For other dimensions, the capacitance can be calculated using the formula

C = 2*(n-1)*A/d

where

- C: capacitance in pF

- A: Area of one aluminium sheet in cm-squared (excluding connection strip)

- n: number of aluminium sheets

- d: thickness of insulation between two aluminium sheets in mm

This formula is valid for PE dielectric only.

[Back to Index]

[Other links]

Jochen

Kronjaeger

Kronjaeg@stud-mailer.uni-marburg.de

The capacity of the above "yoghurt container" cap is by far too low for many purposes. This plate stack cap is intended to be used in a tesla coil circuit and a marx generator. It is designed to withstand at least 30kV DC or 20kV AC with a big safety margin. The dielectric is polyethylen (PE), therefore losses should be low even at higher frequencies. The condcting plates (aluminium foil) are al in parallel, making low internal resistance and inductance. Both low losses and low resistance are important for tesla coil and pulse discharge use.

The capacity of the above "yoghurt container" cap is by far too low for many purposes. This plate stack cap is intended to be used in a tesla coil circuit and a marx generator. It is designed to withstand at least 30kV DC or 20kV AC with a big safety margin. The dielectric is polyethylen (PE), therefore losses should be low even at higher frequencies. The condcting plates (aluminium foil) are al in parallel, making low internal resistance and inductance. Both low losses and low resistance are important for tesla coil and pulse discharge use.

A more elaborate version (sealed airtight, no spraying, no arcing)

is the following:

Get three same plastic

yoghurt containers (PE or PP and rather thick; "Zott Sahnepudding"

serves well and tastes o.k.:-). Also get self-adhesive

aluminium tape (7cm wide). You may find this in DIY markets, it's

original purpose is to seal heat-isolations on hot-water pipe. Put it

on the inside and outside of one container. Fix some kind of terminal

on each of the two others. Connect the terminals to the inside

resp. outside alu layer with a narrow band of alu foil. The three

containers must still fit into one another! Fill some polyester resin

(with hardener of course) into the "outer" and "inner" container and

press all three into one another. Expect the polyester resin to splash

out :-) When the resin has hardened (some hours), the cap is ready and

can be tested. With a not too thin container, it should easily

withstand 30kV. However, the capacity is low due to the small

conducting surface (maybe some 100pF).

A more elaborate version (sealed airtight, no spraying, no arcing)

is the following:

Get three same plastic

yoghurt containers (PE or PP and rather thick; "Zott Sahnepudding"

serves well and tastes o.k.:-). Also get self-adhesive

aluminium tape (7cm wide). You may find this in DIY markets, it's

original purpose is to seal heat-isolations on hot-water pipe. Put it

on the inside and outside of one container. Fix some kind of terminal

on each of the two others. Connect the terminals to the inside

resp. outside alu layer with a narrow band of alu foil. The three

containers must still fit into one another! Fill some polyester resin

(with hardener of course) into the "outer" and "inner" container and

press all three into one another. Expect the polyester resin to splash

out :-) When the resin has hardened (some hours), the cap is ready and

can be tested. With a not too thin container, it should easily

withstand 30kV. However, the capacity is low due to the small

conducting surface (maybe some 100pF).